-

Copper Nickel alloys29 63.546Cucopper28 58.6934Ninickel

-

Copper Nickel Tin Spinodal Alloys29 63.546Cucopper28 58.6934Ninickel50 118.71Sntin

-

Copper Nickel Silicon alloys29 63.546Cucopper28 58.6934Ninickel14 28.0855Sisilicon

-

Nickel Aluminium Bronzes29 63.546Cucopper13 26.9815386Alaluminium

-

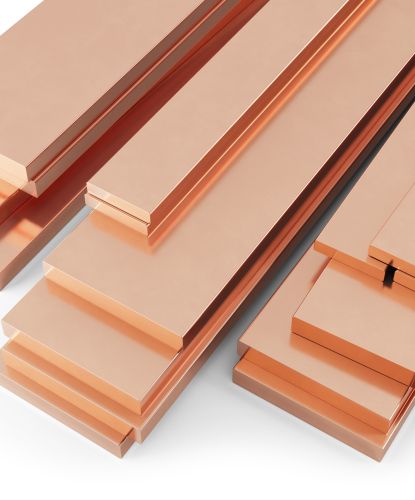

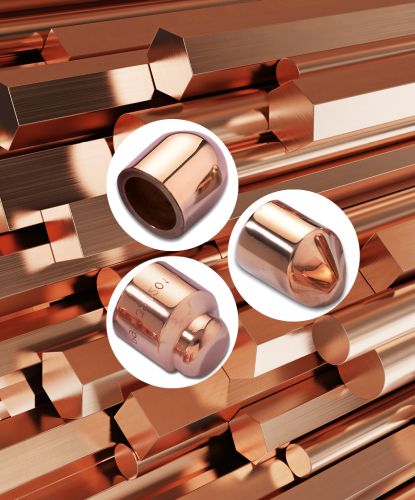

Pure Copper & Low-alloyed Copper29 63.546Cucopper

-

Copper Beryllium alloys29 63.546Cucopper4 9.012182Beberyllium

-

Pure Nickel & Nickel-based alloys28 58.6934Ninickel

-

Nickel-Silver alloys29 63.546Cucopper30 65.409Znzinc28 58.6934Ninickel

-

Copper Manganese alloys29 63.546Cucopper25 54.938045Mnmanganese

-

Special & standard Brass29 63.546Cucopper30 65.409Znzinc

-

Antimicrobial Copper29 63.546Cucopper

-

Tin-Bronzes29 63.546Cucopper50 118.71Sntin

Materials

-

Copper Nickel alloys29 63.546Cucopper28 58.6934Ninickel

-

Copper Nickel Tin Spinodal Alloys29 63.546Cucopper28 58.6934Ninickel50 118.71Sntin

-

Copper Nickel Silicon alloys29 63.546Cucopper28 58.6934Ninickel14 28.0855Sisilicon

-

Nickel Aluminium Bronzes29 63.546Cucopper13 26.9815386Alaluminium

-

Pure Copper & Low-alloyed Copper29 63.546Cucopper

-

Copper Beryllium alloys29 63.546Cucopper4 9.012182Beberyllium

-

Pure Nickel & Nickel-based alloys28 58.6934Ninickel

-

Nickel-Silver alloys29 63.546Cucopper30 65.409Znzinc28 58.6934Ninickel

-

Copper Manganese alloys29 63.546Cucopper25 54.938045Mnmanganese

-

Special & standard Brass29 63.546Cucopper30 65.409Znzinc

-

Antimicrobial Copper29 63.546Cucopper

-

Tin-Bronzes29 63.546Cucopper50 118.71Sntin

- Hardiall® range of spinodal alloys

- Niclafor® 1000 | CuNi9Sn6 | C72700

- Declafor 1015 | CuNi7.5Sn5Te | C72670

- NS30 | CuNi7Si2Cr

- ARCAP®

- K5 & K5B special Copper-Nickel-Aluminium alloys

- K7 | CuNi14Al3Fe1 | WL 2.1504 | LN 9468

- Hardibron® | CuNi14Al3Fe1 | WL 2.1504 | DTD 900/4805

- Navinic anticorrosion alloys

- C63000, AMS4590 and other Aluminium Bronzes

- Welding caps and welding materials: Powerode+® & Alrode®

- Welding alloys in bars and coils

- UC500 | CuCrZr | ASTM B624

- C97® & C98® special low-alloyed Copper

- C99® special low-alloyed Copper

- Si45Z | CuSi3Fe2Zn3 | C65620 | AMS 4616

- Pure Nickel materials

- EnviB X

- Alrode® | CuCrZr | C18147

- Niclal® 43A | CuMn12Ni | CuMn12Ni2

- AB2 | CuAl10Ni | C95800

- Alloy 954 | CuAl10Fe3 | C95400 | CC331G

- PB1 | CuSn10P | C90700

- LG2 | CuSn5Zn5Pb5 | CC491K

- AMS 4880 | CuAl11Ni5Fe5 | C95510

- AMS 4881 | CuAl10Ni5Fe3 | C95520

Key products

- Hardiall® range of spinodal alloys

- Niclafor® 1000 | CuNi9Sn6 | C72700

- Declafor 1015 | CuNi7.5Sn5Te | C72670

- NS30 | CuNi7Si2Cr

- ARCAP®

- K5 & K5B special Copper-Nickel-Aluminium alloys

- K7 | CuNi14Al3Fe1 | WL 2.1504 | LN 9468

- Hardibron® | CuNi14Al3Fe1 | WL 2.1504 | DTD 900/4805

- Navinic anticorrosion alloys

- C63000, AMS4590 and other Aluminium Bronzes

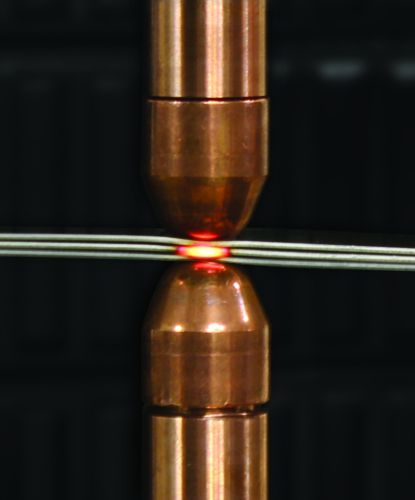

- Welding caps and welding materials: Powerode+® & Alrode®

- Welding alloys in bars and coils

- UC500 | CuCrZr | ASTM B624

- C97® & C98® special low-alloyed Copper

- C99® special low-alloyed Copper

- Si45Z | CuSi3Fe2Zn3 | C65620 | AMS 4616

- Pure Nickel materials

- EnviB X

- Alrode® | CuCrZr | C18147

- Niclal® 43A | CuMn12Ni | CuMn12Ni2

- AB2 | CuAl10Ni | C95800

- Alloy 954 | CuAl10Fe3 | C95400 | CC331G

- PB1 | CuSn10P | C90700

- LG2 | CuSn5Zn5Pb5 | CC491K

- AMS 4880 | CuAl11Ni5Fe5 | C95510

- AMS 4881 | CuAl10Ni5Fe3 | C95520

- Current Sensing & Precision Resistance Alloys

- Electric battery components

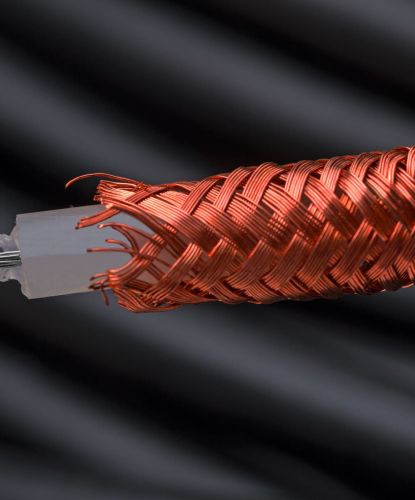

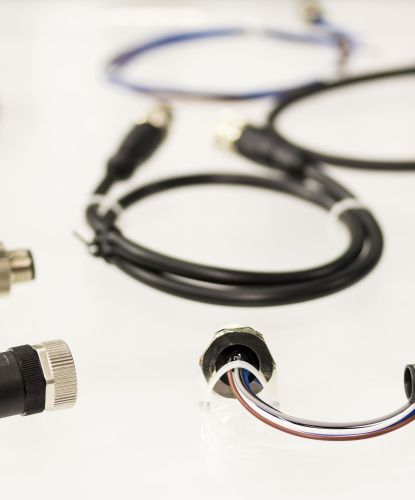

- Cabling for high performances

- Electro-magnetic shielding materials

- Industry parts for high temperature, pressure and wear resistance

- Aerospace mechanical performance parts

- High performance valve train components

- Sea-water circuits high corrosion resistance components

- High performance electric connectors

- Optical fiber connectors

- Railway industry components

- High strength heavy load friction wear resistance

- Oil & Gas High Pressure High Temperature (HPHT) parts

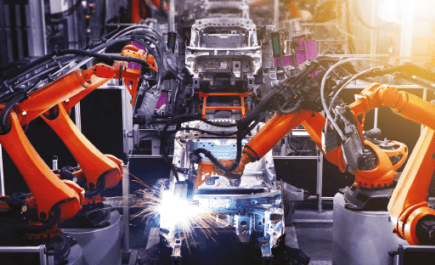

- Resistance welding solutions

- Electric motors & generators: high conductivity & high strength

- Hydrogen storage & distribution: high strength, corrosion & pressure resistance

Applications

- Current Sensing & Precision Resistance Alloys

- Electric battery components

- Cabling for high performances

- Electro-magnetic shielding materials

- Industry parts for high temperature, pressure and wear resistance

- Aerospace mechanical performance parts

- High performance valve train components

- Sea-water circuits high corrosion resistance components

- High performance electric connectors

- Optical fiber connectors

- Railway industry components

- High strength heavy load friction wear resistance

- Oil & Gas High Pressure High Temperature (HPHT) parts

- Resistance welding solutions

- Electric motors & generators: high conductivity & high strength

- Hydrogen storage & distribution: high strength, corrosion & pressure resistance